Testing & Certification

With the stringent conditions required in today’s high-precision manufacturing processes, your facility can benefit from expert assistance to ensure you retain your cleanroom certification. As running the relevant tests on a regular basis to check for any deviations from the norm can be a drain on resources, relying on an expert for cleanroom certification services is often the best choice, both in terms of reduced costs and more effective results.

As one of the leading providers of cleanroom performance testing in Singapore, Cleanzones is the partner you need to guarantee your operations are fully in line with the specified guidelines. We provide end-to-end cleanroom certification services, and can also be relied on to conduct specific procedures like Cleanroom Performance Testing, 21 CFR Part 11 Compliance in Temperature Mapping, or Compressed Dry Air (CDA) testing.

Cleanzones can set up a monitoring and optimisation process that will keep your cleanroom at peak efficiency. We’ll handle the regulatory details so that your team can focus on what is most important – innovation.

CLEANROOM CERTIFICATION

Within a cleanroom environment, operational guidelines and standards are stringent, with a near-zero margin for error. Thus, to the operator of a cleanroom, certification is of utmost importance as a mark of quality assurance and regulatory compliance. Similarly, a provider of cleanroom certification services needs to be recognised as having the correct competencies and capabilities to conduct such an assessment. As one of the few cleanroom certification service providers to have acquired NEBB Certification in Singapore, Cleanzones is uniquely positioned to give your facility a quality assurance advantage. Achieving cleanroom certification with Cleanzones can serve as evidence that your facility meets the NEBB’s cleanroom certification standards, assuring both local and international partners of your operational excellence.

Our cleanroom certification services are geared to ensure your operations are in line with international standards and guidelines, including:

- ISO 14644

- cGMP / PICs

- IEST

- BS 5295

- ISO 8573-1

- 21 CFR Part 11 Compliance

CLEANROOM PERFORMANCE TESTING IN SINGAPORE

If you require specific cleanroom testing procedures to be conducted, we can assist you with the following to ensure that your cleanroom and clean air devices provide the necessary clean air for your work processes:

- Airflow Velocity and Uniformity Test

- HEPA/ULPA Filter Installation Leak Test

- Airborne Particle Count Test

- Noise Level Test

- Airflow Pattern Test

- Light Intensity Test

- UV Light Test

- Differential Pressure

- Room Recovery

- Floor & Wall Resistance

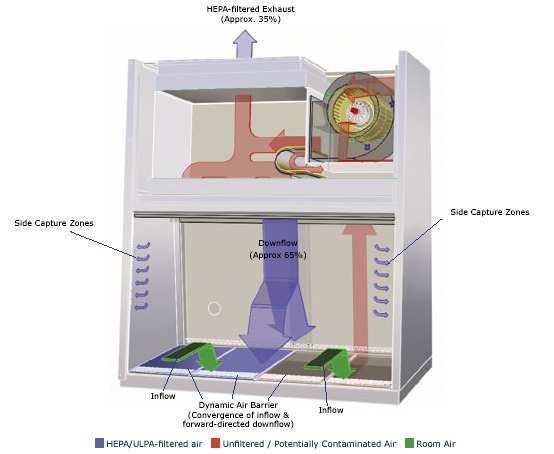

Airflow Visualisation

To demonstrate the actual airflow pattern throughout the work zone of the cleanroom.

Illustrate the effects on room airflow by the process equipment tooling within the work zone.

CLEAN-AIR DEVICES CERTIFICATION & MAINTENANCE

UNIDIRECTIONAL FLOW CABINET

AIRSHOWER

FUMEHOOD CABINET

BIO-HAZARD SAFETY CABINET

CLEANBOOTH

ISOLATOR CYTOTOXIC DISPENSING

Compressed Dry Air (CDA) Testing

Compressed Dry Air (CDA) Testing is a crucial service for maintaining the integrity and performance of cleanrooms or controlled environments. It ensures that the risk of contamination is under control and that the relevant processes are using clean compressed dry air. CDA testing ensures that it meets stringent purity standards, and is free from particulates, oil, moisture, and other contaminants that could compromise sensitive operations.

Conformity with ISO 8573.1:2010 Compressed Air Quality Standard

We offer a complete range of testing services to assess the compressed air quality in your plant and maintain it in line with international specifications, which is especially important for critical applications in Pharmaceutical & Semiconductor facilities.

- Purity Test @ 0.1μm particle size (count/m3)

- Oil Mist Content Test (mg/m3)

- Water Vapor Content Test (g/m3)

- Pressure Dew Point Test (°Ctd)

- Microbial Count Test (cfu/m3)

- Total Hydrocarbon Content Test (ppm)

- Carbon Monoxide Test (..and other gases)

Humidity/Temperature Mapping Services

Temperature mapping services involve the systematic measurement and documentation of temperature distribution within a cleanroom or controlled environment over a specified period. Advanced data logging equipment is used to perform comprehensive assessments, identifying any hotspots or fluctuations that could compromise operations. In addition to helping meet regulatory requirements, temperature mapping services can point out potential risk points as well as areas that can undergo optimization, enhancing operational efficiency.

Our expert humidity and temperature mapping services can result in several benefits to your facility, such as:

- Maintaining consistent temperature and humidity levels to improve warehouse & cold room conditions

- Eliminating temperature-related product failures, saving the time and money spent on rectifying such errors

- Aiding in regulatory compliance like 21 CFR Part II

- Identifying problem hot-spots in racking, shelving, and pallet storage systems

Electronic Data logging

(wireless & non-wireless)

- Measurement : Temperature (°C) Humidity (%)

- Resolution : 0.1°C / 0.1% RH

- Accuracy : ±0.5°C / ±3% RH

- Measuring range : -20~+70°C/0~100

- Measuring rate : 2 secs to 24 hours

HVAC Air Balancing

HVAC air balancing is a critical process in maintaining the optimal performance and efficiency of heating, ventilation, and air conditioning systems, especially in cleanroom environments. This process involves measuring and adjusting the airflow within the system to ensure that the correct volume of air is delivered to each space, and that the specified temperature, humidity, and cleanliness levels are maintained by the HVAC. Air balancing should ideally be carried out when setting up a cleanroom to ensure the layout is optimally efficient.

No matter the type of HVAC system you rely on, our experienced team can support you with air balancing services to achieve the requirements of your cleanroom processes.

- Airflow Volume

- Room Total Air Change Rate

- Room Differential Pressure

Duct Leak Test

DW/144 & DW/143

Ductwork Leakage Testing

We conduct thorough duct leak testing procedures to accurately assess the following:

- Supply & Return Duct

- Allowable Leakage & Actual Leakage

- Leakage Class

- SMACNA HVAC Air Duct Leakage Test

Manual 1st Edition 1985

Fumigation Procedures

(Cleanrooms, Pharmaceutical Operations, and Hospitals)

For fumigation, we employ a time-tested and effective decontamination procedure using hydrogen peroxide mist as a broad-spectrum disinfectant to curb microbial and fungal contamination to acceptable levels.

This solution is ecologically safe, being biodegradable and non-carcinogenic as it breaks down chemically into water and oxygen. Further, the Swiss-formulated disinfectant we use is odorless, temperature-stable, non-heated, and leaves no residue.

Singapore:

Address:

2 Gambas Crescent #09-10 Nordcom II Singapore 757044

Open Hours:

9am – 6pm

Malaysia:

Address:

No.17-1 Jalan DU 1/2,

Taman Damai Utama, 47180 Puchong,

Selangor Darul Ehsan, Malaysia

Contact:

Open Hours:

9am – 6pm